Prices of solar panels have finally come down to reasonable prices. Also the "flexible" panels make fitting much easier as well as significantly lighter. Photonic Universe on eBay had an offer for 1/3 off 100W panel at £140 - which in retrospect seems genuine since they are £215 today.

I decided that, since I was unlikely to use the panel over the winter, that I should make it removable.

I also plan to fit a roofbox this year, and long term it may make more sense to mount the panel on the roofbox.

So rather than glue the panel directly to the roof I sourced some plastic "j" section so that the panel could slide in on out.

After much searching around I found this from www.claddingwarehouse.co.uk

2.5mm kpanel edge strip

You can get it in 2 or 3 metre lengths for £3 or £4, and shipping is only £3.50

Initially I tried using Tiger Seal to stick the rail down - which worked really well with the Aluminum awning rail. But after 3 attempts I came to the conclusion that this material wasn't in the "works with most plastics" category. Some Evo "sticks like s**t" did the job.

To stop any would be thieves I used a couple of domed coach bolt screwed into the rear roofrack fixings.

To feed the wires through the roof, people typically use these

These ugly bits of plastic cost about £10.

The underside is open, so if you have a problem with the sealant you will get water ingress - and no way of knowing you have problem.

The other problem I found was that the cable glands were too big for solar panel cables - probably because they are usually used to TV/Satellite cables

A much neater solution was to use a solar panel junction box

These don't seem to be available in the UK, though they are easy enough to get on eBay from Hong Kong - or maybe Germany.

It very easy to open the box to check if water is getting in.

So I removed the internal connectors, and just fed the wires though holes (with grommets) in the roof, and stuck the box down with Tiger Seal

Here's the finished article.

The cables are terminated with MC4 connectors which plug into the solar panel connectors.

There are loads of solar controllers on eBay, many claiming to support MPPT, which is basically a method of supplying the battery with maximum available current at the optimum voltage, regardless of whatever voltage is coming from the panel. Unfortunately many of eBay models are fake, using the standard PWM type charging, which is less efficient, or even worse, just a bunch of bits that look like its a controller. I eventually went for a German designed Votronic MPP165 from an eBay seller from New Zealand for about £55. It arrived within a week and seems to be genuine, though I haven't got the time (or inclination) to do proper testing - unlike the dozens of people posting on YouTube. I sent a few questions to the manufacturers in Germany, and they were very helpful and quick to respond.

Build diary for micro camper conversion. Base vehicle is a 2002 Peugeot Expert 1.9D adapted for wheel chair access (WAV)

Friday 20 February 2015

Thursday 19 February 2015

Rain Shields

On the odd occasion we are stuck inside the van, due to its small size, the sliding door and windows are usually open. This is also very important if cooking, to allow steam out. The only problem with this is that the rain comes in. The sun shade will stop this, but I know that it won't always be put up, unless we are staying put for a while. Again something quick & simple was required.

With the left over material from the sun shade, two smaller shades were run up, with awning piping sewn on one edge, and open seams for fiberglass poles on the other 3 sides.

To support the fiberglass poles I used Tiger seal to attach a length of U channel aluminium to the roof. The channel needed a slight bend at each end to fit the curve of the roof. Then I glued in some round aluminium into the channel - which was left straight so that the poles can be inserted easily.

The aluminium can be bought at Wickes - I had to bring the poles along to make sure they fitted since sizes can vary quite a bit.

Poles inserted, with awning piping inserted into C channel

Rain shield outside cooker window

Rain shield over sliding door

In theory, if rain collects, the weight will cause the shield to drop, and the excess will drip off. Though if it's raining that heavily the door will be shut anyway.

With the left over material from the sun shade, two smaller shades were run up, with awning piping sewn on one edge, and open seams for fiberglass poles on the other 3 sides.

To support the fiberglass poles I used Tiger seal to attach a length of U channel aluminium to the roof. The channel needed a slight bend at each end to fit the curve of the roof. Then I glued in some round aluminium into the channel - which was left straight so that the poles can be inserted easily.

The aluminium can be bought at Wickes - I had to bring the poles along to make sure they fitted since sizes can vary quite a bit.

Poles inserted, with awning piping inserted into C channel

Rain shield outside cooker window

Rain shield over sliding door

In theory, if rain collects, the weight will cause the shield to drop, and the excess will drip off. Though if it's raining that heavily the door will be shut anyway.

Wednesday 18 February 2015

Sun Shade

On last years trip, we made a very simple sun shade, using a Eurohike tarp. It did the job very well, until it rained. Water would collect in the middle of the tarp, and the weight would pull the pegs out slightly, allowing more water to gather. Eventually the light polyester material stretched in the middle, making the problem even worse.

There are plenty of awning and sunshades designed for caravans and motorhomes, but I simply could not find any that would suit a micro camper. The closest was the Fiamma Caravanstor 190cm, but I felt that this was too bulky (and pricey at £200+). NR Awnings do make one that would have been perfect, for £79, however the length at 2.4m was just too long, and they were unwilling to modify. I did like the design however and decided to make our own.

I wanted the material to have a high tensile strength so that it could be tensioned, to avoid pockets that rain could collect in, but not too heavy, so that it's easy to roll and store.

Dutch manufactured acrylic coated polyester, TenCate all-season WR-18 fitted the bill, with 100/140daN tensile strength and 2daN tearing strength, and at 240g/m3 it's reasonably light weight.

The quoted water column is >850mm, which compares very well to commercial awnings.

I ordered 204cm X 2.7m, and 125m of waterproof thread, from https://www.esvocampingshop.com in the Netherlands, for around €55.

For attaching the main sun shade to the van I used the standard 6mm awning piping, which was sewn on. This is pretty easy to source on eBay.

To fix the shade to van I wanted an aluminum J rail, rather than plastic, for maximum strength.

I eventually sourced a rail used for Fiamma F35 awnings.

The problem with this though, is that it comes in 3m sections, which makes it costly to ship. In fact most suppliers won't even ship it without buying the full awning.

Fortunately Riversway sell them (search for "Fiamma Adapter Rail") for £15.95 plus £6.95 shipping.

To fix the rail to the roof I used Tiger Seal, which once set has a little bit of flex, so hopefully I wont have problems with expansion stresses.

Here is the final result. approx 2m x 2m.

There are plenty of awning and sunshades designed for caravans and motorhomes, but I simply could not find any that would suit a micro camper. The closest was the Fiamma Caravanstor 190cm, but I felt that this was too bulky (and pricey at £200+). NR Awnings do make one that would have been perfect, for £79, however the length at 2.4m was just too long, and they were unwilling to modify. I did like the design however and decided to make our own.

I wanted the material to have a high tensile strength so that it could be tensioned, to avoid pockets that rain could collect in, but not too heavy, so that it's easy to roll and store.

Dutch manufactured acrylic coated polyester, TenCate all-season WR-18 fitted the bill, with 100/140daN tensile strength and 2daN tearing strength, and at 240g/m3 it's reasonably light weight.

The quoted water column is >850mm, which compares very well to commercial awnings.

I ordered 204cm X 2.7m, and 125m of waterproof thread, from https://www.esvocampingshop.com in the Netherlands, for around €55.

For attaching the main sun shade to the van I used the standard 6mm awning piping, which was sewn on. This is pretty easy to source on eBay.

To fix the shade to van I wanted an aluminum J rail, rather than plastic, for maximum strength.

I eventually sourced a rail used for Fiamma F35 awnings.

The problem with this though, is that it comes in 3m sections, which makes it costly to ship. In fact most suppliers won't even ship it without buying the full awning.

Fortunately Riversway sell them (search for "Fiamma Adapter Rail") for £15.95 plus £6.95 shipping.

To fix the rail to the roof I used Tiger Seal, which once set has a little bit of flex, so hopefully I wont have problems with expansion stresses.

Notches needed to be cut out to allow clearance for the roof rack mounting points

As and alternative to punching eyelets, which would require reinforcing the surrounding area I'm trying Holdon Midi clips. These push on and claim to be able to hold 75kg, and can be got for about £1.50 each.

Tuesday 17 February 2015

(WAV) Exhaust Problems

Although the van passed the MOT, there was an advisory about the exhaust.

I had been dreading this one, since I could see that as a result of the original lowering of the floor for wheel chair access, the exhaust had been re-routed, and was more than likely a custom install.

This was the damage

I guess I could have patched it up, but past experience suggested that it was just a matter of time before the rest of the exhaust went the same way.

A quick visit to the local exhaust fitters confirmed that that it would need a specialist.

I contacted some of the garages that specialise in WAV exhuasts, and was told it would probably be in the region of £600 or £700 to replace, which is shocking considering a Peuegeot backbox can be got for ~£30.

A cheaper option was to go to one of the boy racer outfits that supply aftermarket shiny stainless steel exhausts. The main players at the low end of the UK market, are Longlife and Powerflow, who are now owned by the same group. Though it was a bit odd asking the fitters to make the exhaust as quiet as possible, but Top Gear in Watford were pleasant enough and reasonable (for this kind of thing) at £300 for replacing the backbox and mid-section, with a lifetime guarantee.

As an added bonus the new exhaust is much smaller, which gives a few more inches clearance off the ground.

I had been dreading this one, since I could see that as a result of the original lowering of the floor for wheel chair access, the exhaust had been re-routed, and was more than likely a custom install.

This was the damage

I guess I could have patched it up, but past experience suggested that it was just a matter of time before the rest of the exhaust went the same way.

A quick visit to the local exhaust fitters confirmed that that it would need a specialist.

I contacted some of the garages that specialise in WAV exhuasts, and was told it would probably be in the region of £600 or £700 to replace, which is shocking considering a Peuegeot backbox can be got for ~£30.

A cheaper option was to go to one of the boy racer outfits that supply aftermarket shiny stainless steel exhausts. The main players at the low end of the UK market, are Longlife and Powerflow, who are now owned by the same group. Though it was a bit odd asking the fitters to make the exhaust as quiet as possible, but Top Gear in Watford were pleasant enough and reasonable (for this kind of thing) at £300 for replacing the backbox and mid-section, with a lifetime guarantee.

As an added bonus the new exhaust is much smaller, which gives a few more inches clearance off the ground.

Friday 13 February 2015

Leisure Battery Wiring

Update 15th May 2016

The meters with current shunt proved to be inaccurate because the supply circuit and the measuring circuits are not isolated. I bought some B0505S 1W 5V DC to DC converters, which allowed the 5V supply to float. Now the midday sun in SE England in May was giving me a reading of 4A into the battery, whereas before it was about half that.

-- end

Leisure Battery Charging Circuit

Without doubt batteries and charging causes the greatest amount of confusion on the online forums. This is not helped by the suppliers intent in making users part with as much money as possible.

Even tring to ascertain if a battery is actually deep cycle is very difficult.

One thing I do believe though is that flooded lead acid is the simplest and most robust tech. As long as the battery is not seriously discharged, and is maintained correctly, then they should last a long time. Multi-stage charging is key to this, but the costs are high.

My approach is to use a solar panel with mppt controller, coupled with alternator charging when traveling (if required). In addition I have a ctek charger permanently connected, so I can topup if on hook up.

There are three states

1) Engine off - Solar charges Leisure battery & any spare goes to the Starter Battery. The leisure battery supplies the fridge etc.

2) Engine running - Solar still charges Leisure battery but the alternator supplies the fridge etc.

3) Engine running - Alternator supplies the fridge etc. and also charges the leisure battery. This is selected via the 2nd switched relay.

I way lucky with the wiring on the Expert, in that there is an "engine running" relay that I was able to pick up using a piggy back fuse connector. This saves having to draw current from the alternator sense wire - which can cause unexpected results.

Relay block with fuses

Finished controller, in the passenger footwell, with the relay unit sitting above under the glovebox

Overall the design should provide controlled charging via solar along with the chance to optionally boost the charging via the alternator.

To monitor what is going on, I fitted a couple of current measuring shunts - one in the leisure battery return, and one in the Fridge and Lights return so I can get some idea of the current in and out of the battery.

These are cheapo eBay meters from the far east. One problem that I did think of, is that these meters do not show reverse current - so the top one shows the current into the battery, and the bottom one show the current consumed by the fridge etc. They have separate connections for the meter supply, but I was getting very odd results, until I disconnected the ground wires. They are not ideal, but for £10, they will do for now

I'm started using very conservative fuses - 15A between the starter & leisure battery and 40A relays.

However I ran the fridge for a while to run the battery down to 50%, and checked the current flow when the alternator kicked in. I was a very surprised to see this initial inrush was almost 30A. It did reduce after a few moments, but it was way higher than I expected. I do wonder what current would flow if the battery was severely depleted, and what it would do to my 40A relay!

The meters with current shunt proved to be inaccurate because the supply circuit and the measuring circuits are not isolated. I bought some B0505S 1W 5V DC to DC converters, which allowed the 5V supply to float. Now the midday sun in SE England in May was giving me a reading of 4A into the battery, whereas before it was about half that.

-- end

Leisure Battery Charging Circuit

Without doubt batteries and charging causes the greatest amount of confusion on the online forums. This is not helped by the suppliers intent in making users part with as much money as possible.

Even tring to ascertain if a battery is actually deep cycle is very difficult.

One thing I do believe though is that flooded lead acid is the simplest and most robust tech. As long as the battery is not seriously discharged, and is maintained correctly, then they should last a long time. Multi-stage charging is key to this, but the costs are high.

My approach is to use a solar panel with mppt controller, coupled with alternator charging when traveling (if required). In addition I have a ctek charger permanently connected, so I can topup if on hook up.

There are three states

1) Engine off - Solar charges Leisure battery & any spare goes to the Starter Battery. The leisure battery supplies the fridge etc.

2) Engine running - Solar still charges Leisure battery but the alternator supplies the fridge etc.

3) Engine running - Alternator supplies the fridge etc. and also charges the leisure battery. This is selected via the 2nd switched relay.

I way lucky with the wiring on the Expert, in that there is an "engine running" relay that I was able to pick up using a piggy back fuse connector. This saves having to draw current from the alternator sense wire - which can cause unexpected results.

Relay block with fuses

Finished controller, in the passenger footwell, with the relay unit sitting above under the glovebox

Overall the design should provide controlled charging via solar along with the chance to optionally boost the charging via the alternator.

To monitor what is going on, I fitted a couple of current measuring shunts - one in the leisure battery return, and one in the Fridge and Lights return so I can get some idea of the current in and out of the battery.

These are cheapo eBay meters from the far east. One problem that I did think of, is that these meters do not show reverse current - so the top one shows the current into the battery, and the bottom one show the current consumed by the fridge etc. They have separate connections for the meter supply, but I was getting very odd results, until I disconnected the ground wires. They are not ideal, but for £10, they will do for now

I'm started using very conservative fuses - 15A between the starter & leisure battery and 40A relays.

However I ran the fridge for a while to run the battery down to 50%, and checked the current flow when the alternator kicked in. I was a very surprised to see this initial inrush was almost 30A. It did reduce after a few moments, but it was way higher than I expected. I do wonder what current would flow if the battery was severely depleted, and what it would do to my 40A relay!

Wednesday 4 February 2015

Leisure Battery

Initially I did not plan to add a leisure battery, since our style of travel usually means that we park up for 3 days at a time. Also the van being very small, means that we tend to live outside the van rather than inside. All of this means that the "aires" don't really suit us, especially since we try to spend as much time out and about, rather than at the van.

After our inaugural 4 month trip, the strategy proved to be correct, with one small exception. On travel days, away from electric hookup, the Tropicool coolbox struggled to keep things cool all day. Especially if we stopped off for a few hours to sight-see. So as part of the winter upgrade, I splashed out on a new Waeco CRP40 compressor fridge, which meant that I needed the leisure battery after all.

I had considered putting the battery behind the drivers seat, and reducing the size of the water container. For safety reasons, this would mean using an AGM battery. After spending a lot of time reading about various batteries, I came to the conclusion that a deep cycle flooded lead acid battery would be best. So I settled on 80AH Banner Energy Bull - which is the largest size I can fit in. Although the battery is spec as 80AH, I'll not get anything like that out of it. During use it should not really be discharged below 50% - and when its charging everything slows down after about 80%. So I reckon that you can only rely on about 25AH being available. It's a pessimistic view but it should let me run the fridge for a day while stationary & in overcast weather.

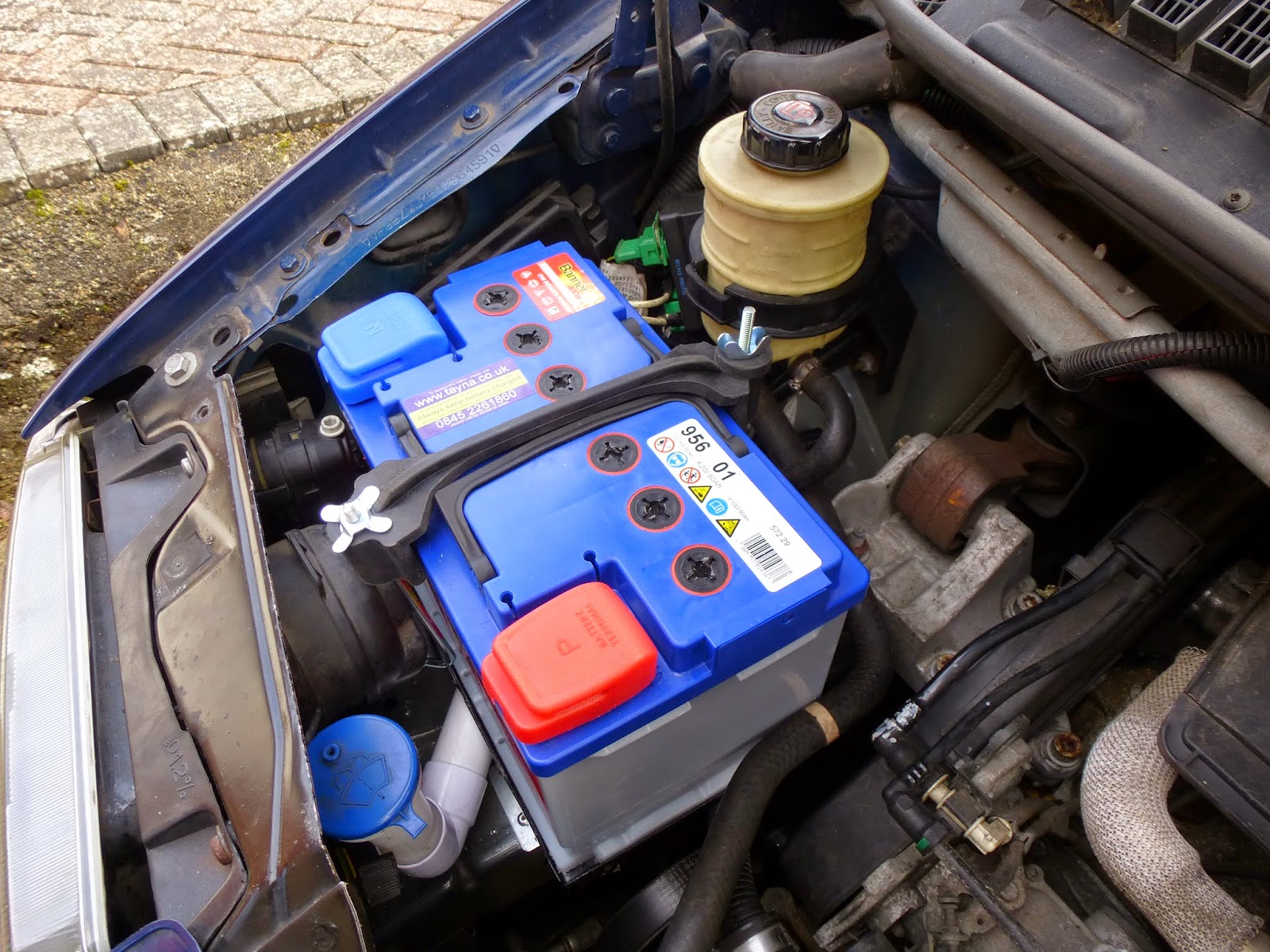

This meant that I had to mount the battery in a ventilated area. I knew that some people had already put a battery in the engine bay, so this is where I put it .

http://cornishben.smugmug.com/General/The-Van-Conversion/i-ft6ZTGk

http://www.soapy.freeola.com/campervan/joblist.html#E (pictures are broken)

This is the area where the battery is going to go

The glow plug relay bracket, to the left of the water filler was removed. The relays were eventually mounted up behind the power steering filler bottle.

The water filler was sawn off, and some 32mm FloPlast ABS solvent waste pipe (B&Q) fitted perfectly.

To secure the battery I found this 7" x 11" battery tray, which is ideal for a 096 battery.

To support the tray I modified some 150mm x 150mm x 63mm galvanised steel right angle brackets.

To level up the battery the bracket legs are different heights - so a little trial and error using wooden blocks, to end up with right heights (almost). Bending with just a vice and a club hammer made it a very slow job.

Brackets fitted using pop rivets - not ideal, but there was no access to the other side. The top of the brackets are pretty much flush with the top of the plastic pipe. This also gives enough room for the power steering hoses - though I ended up moving the hose behind the cable harness (green stripe)

Battery tray in place, bolted to the brackets

Battery fitted. I opted for a rubber clamp, since I though it may be lower profile than a metal one. The wing nut at the front had to be flattened, so that there was enough room to close the bonnet.

This battery is 278L x 175W x 190H and there is very little room to spare.

After our inaugural 4 month trip, the strategy proved to be correct, with one small exception. On travel days, away from electric hookup, the Tropicool coolbox struggled to keep things cool all day. Especially if we stopped off for a few hours to sight-see. So as part of the winter upgrade, I splashed out on a new Waeco CRP40 compressor fridge, which meant that I needed the leisure battery after all.

I had considered putting the battery behind the drivers seat, and reducing the size of the water container. For safety reasons, this would mean using an AGM battery. After spending a lot of time reading about various batteries, I came to the conclusion that a deep cycle flooded lead acid battery would be best. So I settled on 80AH Banner Energy Bull - which is the largest size I can fit in. Although the battery is spec as 80AH, I'll not get anything like that out of it. During use it should not really be discharged below 50% - and when its charging everything slows down after about 80%. So I reckon that you can only rely on about 25AH being available. It's a pessimistic view but it should let me run the fridge for a day while stationary & in overcast weather.

This meant that I had to mount the battery in a ventilated area. I knew that some people had already put a battery in the engine bay, so this is where I put it .

http://cornishben.smugmug.com/General/The-Van-Conversion/i-ft6ZTGk

http://www.soapy.freeola.com/campervan/joblist.html#E (pictures are broken)

This is the area where the battery is going to go

The glow plug relay bracket, to the left of the water filler was removed. The relays were eventually mounted up behind the power steering filler bottle.

The water filler was sawn off, and some 32mm FloPlast ABS solvent waste pipe (B&Q) fitted perfectly.

To secure the battery I found this 7" x 11" battery tray, which is ideal for a 096 battery.

To support the tray I modified some 150mm x 150mm x 63mm galvanised steel right angle brackets.

To level up the battery the bracket legs are different heights - so a little trial and error using wooden blocks, to end up with right heights (almost). Bending with just a vice and a club hammer made it a very slow job.

Brackets fitted using pop rivets - not ideal, but there was no access to the other side. The top of the brackets are pretty much flush with the top of the plastic pipe. This also gives enough room for the power steering hoses - though I ended up moving the hose behind the cable harness (green stripe)

Battery tray in place, bolted to the brackets

Battery fitted. I opted for a rubber clamp, since I though it may be lower profile than a metal one. The wing nut at the front had to be flattened, so that there was enough room to close the bonnet.

This battery is 278L x 175W x 190H and there is very little room to spare.

Subscribe to:

Posts (Atom)